“This post shows a summarizd knowledge from Essentials of Supply Chain Management, 3rd ed. written by Michael Hugos, author.”

1 – Key Concepts of Supply Chain Management

- A supply chain is the network from suppliers → production → warehouses/distribution → retail → customers. The goal is to reduce cost, improve responsiveness, and enhance customer service.

- Five key drivers:

- Production: planning and managing production capacity. There are two approach of manufacturing is product focus and functional focus. WH will storage product depending on SKU (Stock keeping unit storage); batch (job lot storage) or cross-docking.

- Inventory: acts as a buffer but also adds cost. There are three method of inventory is Cycle Inventory, Safety Inventory & Seasonal Inventory.

- Location: plant and warehouse location greatly impact cost and service time. Factors to consider include facility costs, labor, workforce skills, infrastructure, taxes, and proximity to suppliers/customers

- Transportation: choosing the right mode (road, sea, air) to optimize cost and speed. Six basic modes of transportation: Ship, Truck, Rail, Pipeline, Airplane, Electronic transportation.

- Information: the core element for managing and optimizing the entire chain. It aim to Coordinate daily activities, and Forecasting and planning

- Principle: balance between cost efficiency and responsiveness.

- Evolution: from vertical integration to virtual integration.

- Examples of SCM as competitive advantage: Wal-Mart (IT for inventory management), Alexander the Great (military logistics).

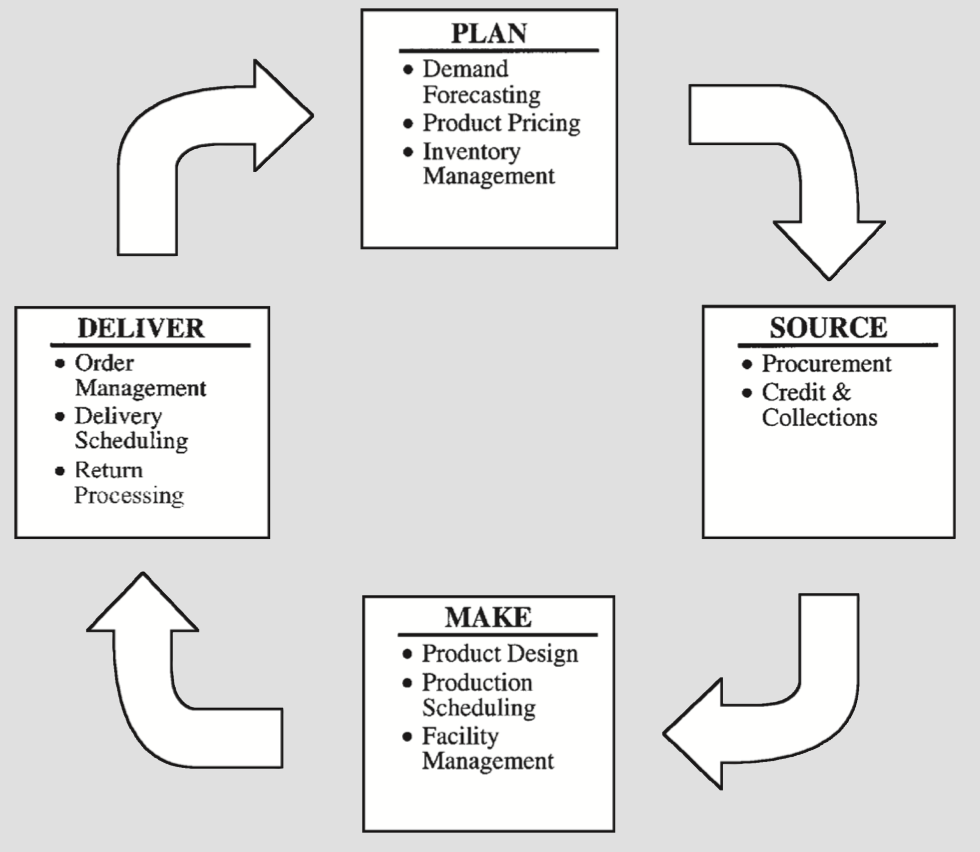

2 – SC Operations: Planning – Sourcing – Making – Delivery

- Demand forecasting & Planning: is the foundation of the entire supply chain. It decide product type, quantity and when needing to order, depending on supply + Demand + product characteristics + competitive environment.

- It combines historical data with market knowledge. Forecasts are never perfect, largely based on forecasting methods such as Qualitative, Casual, Time series and Simulation → must combine statistics and expert judgment.

- Before coming to aggregate planning (3-18 months). That can be decision based on Production rates, capacity utilization, workforce size, inventories, backlogs, distribution. → Three basis approach: product pricing, inventory management and Economic order quantity – EOQ.

- Bullwhip Effect: demand fluctuations get amplified upstream, causing excess inventory.

→ Solutions: share POS data, use CPFR, EDI.

- Sourcing: selecting and managing suppliers; classify into strategic, important, or standard. Consider trade-offs among cost, quality, risk, and long-term relationship.

- Procurement with five main activity categories: Purchasing (direct/strategic materials, MRO) → Consumption Management → Vendor Selection → Contract Negotiation → Contract Management.

- Cross-cultural negotiation experience in negotiating cultures between countries, personal relationships, verbal vs. numerical communication, individual vs. collective, negotiation styles.

- Total Cost of Ownership – TCO: Select vendor is not only depend on price but also time delivery, quality and business capacity.

- Credit and Collections consist of Set credit, and Collections practices & Manage Credit Risk.

- Supply chain strategies:

- Lean supply chain: cost efficiency, waste reduction.

- Agile supply chain: speed, flexibility to adapt to changes.

- Leagile: combining both.

- Case study: Dell – build-to-order supply chain reduces inventory.

- Production models:

- Production schedualing: Allocate available capacity (equipment, labor, facilities) → get highest performance and profit.

- Production must consider to economic lot size and run-out-time.

- There are four classic production strategies including:

- Make-to-Stock (MTS),

- Assemble-to-Order (ATO),

- Make-to-Order (MTO),

- Enginner-to-Order (ETO)

- Distribution: logistics networks and warehouse roles.

- Order management.

- Delivery schedualing: Direct deliveries and Milk Run deliveries (Saving matrix technique and Generalized assignment technique).

- Two delivery sources: Single-Product locations and Distribution Centers, including crossdocking

- Return Processing: surplus or damaged product, defect or re-call goods.

- Transportation: trade-offs of cost and speed (air vs sea vs land).

- Trade-off: customer service vs transportation cost and delivery speed.

3 – Using Information Technology

- IT is equal to the backbone of supply chains; it contain a huge of databases (SQL), Data manipulation and reporting.

- Core systems include ERP, EDI, CRM, SCM, WMS, TMS softwares, etc

- ERP – Enterprise Resource Planning (e.g SAP, Oracle NetSuite, Odoo) is an integrated system for managing the entire enterprise. It covers multiple departments: finance, accounting, production, HR, procurement, sales to ensures centralized data and faster decision-making.

- Procurement Systems: Optimising procurement process, vendor management, tendering & price, order history, etc.

- EDI – Electronic Data Interchange is a standard for electronic data exchange between companies and their partners (suppliers, customers, logistics), replacing paper documents (invoices, purchase orders, bills of lading).

- CRM – Customer Relationship Management manages customer information, transaction history, and after-sales service, supports marketing, sales, and customer support.

- SCM – Supply Chain Management (e.g Kinaxis, Blue Yonder (JDA), SAP SCM) is an specialized software for planning, optimizing, and operating the supply chain, including demand forecasting, production planning, distribution, and transportation management.

- WMS – Warehouse Management System controls inbound, outbound, and inventory; tracks item locations; supports FIFO/FEFO, cross-docking.

- TMS – Transportation Management System manages transportation: route planning, mode selection, shipment tracking, helping to optimize transportation costs and improves delivery performance.

- Importance of IT applied in SCM is visibility (transparency) and real-time data.

- Applications: RFID, E-commerce, cloud computing, simulation modeling, power BI, etc. → IT integration reduces delays and mitigates the bullwhip effect.

4 – Metrics for Measuring Performance

- KPIs are essential for measuring and improving supply chains.

- Metrics groups:

- Customer: satisfaction, on-time delivery rate. → Build-to-Stock (BTS) and Build-to-Order (BT0)

- Financial: Inventory turnover/value, supply chain ROI, ROS; cash-to-cash cycle time.

- Operations: Order/Activity cycle time, Upside/outside flexibility, logistics cost.

- Balanced Scorecard for SCM: Financial, Customer, Internal Processes, Learning & Growth.

- Case study: using KPIs to identify bottlenecks.

5 – Supply Chain Coordination

- Problem: each party optimizes locally → supply chain inefficiency. → bullwhip effect.

- Solution: collaboration, information sharing, binding contracts.

- Collaboration in supply chain: Demand forecasting, order batching, product rationing, product pricing, performance incentives.

- Product Classification: United Nations Standard Products and Services Code – UNSPSC (segment, family, class, commodity, business function); GS1 Global Product Code – GPC

- Models: VMI (Vendor-Managed Inventory), CPFR (Collaborative Planning, Forecasting, and Replenishment), Sales and Operations Planning – S&OP (Sales forecasting, demand planning, supply planning, plan finalization and declaration)

- Success factors: trust, transparency, shared benefits

6 – Innovation for the Real-Time Economy

- Trend: real-time economy.

- Innovation through IT, data, simulation.

- SCM Globe: a supply chain simulation game → learn design & operation.

- Innovation based on online data and global connectivity.

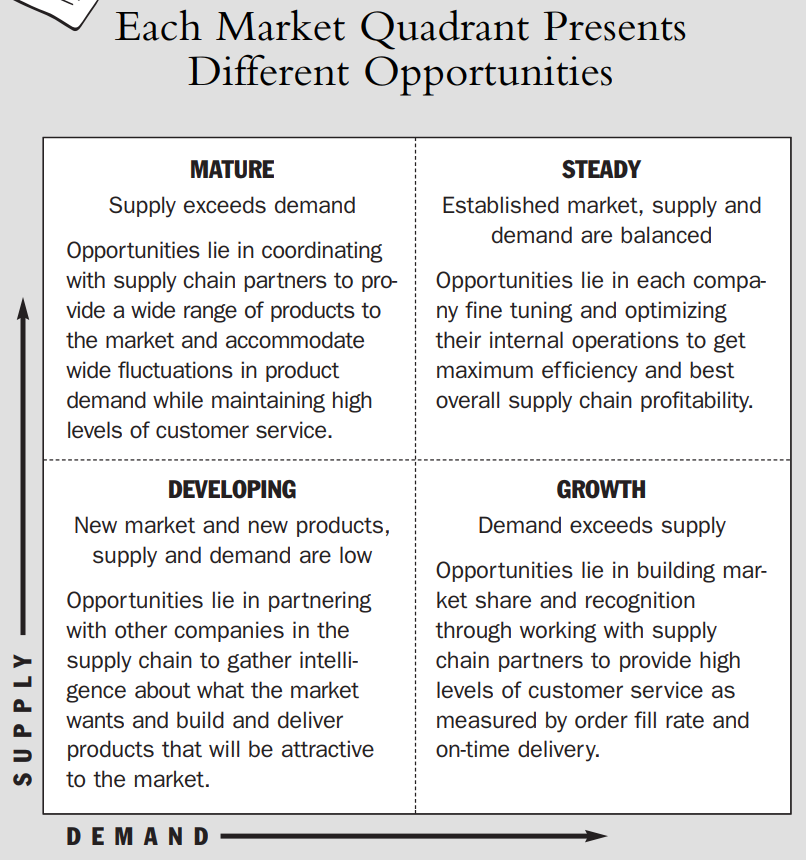

7 – Defining Supply Chain Opportunities

- Identify opportunities by analyzing markets, customers, and internal processes.

- Use SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) for SCM.

- Helps detect weaknesses and gaps → strategic opportunities.

- Examples: leveraging poorly managed logistics or weak customer service.

8 – Creating Supply Chains for Competitive Advantage

- Building SCM as a competitive weapon.

- Must align business strategy with supply chain strategy.

- Steps:

- Identify target markets.

- Define core competencies.

- Build strategic partnerships.

- Measure & continuously improve.

- Case studies: one service company and one manufacturing company.

9 – The Promise of the Real-Time Supply Chain

- Real-time SCM: connected, flexible, transparent.

- Trends: globalization, e-commerce, digital technology.

- Benefits: cost reduction, faster response, better customer service.

- Role of global partnerships.

- Future: big data, AI, automation, sustainability.

Leave a comment