“Crayons are a type of stationery commonly used by children for drawing and decoration. The main ingredients of crayons are paraffin wax and pigment, similar to oil pastel.“

1 – Raw materials:

- Paraffin wax (or beeswax, carnauba wax): act as substrate which provides a solid stick, easy to hold, less messy.

- Pigments: inorganic (oxides, metal salts) or organic (azo, phthalocyanine, etc.). → create hue and tint when applying.

- Additives:

- Mineral oil: used in small amounts, help creates softness and smoothness, reducing brittleness.

- Dispersing agents: can be calcium/zinc stearate, magnesium stearate or non-ionic surfactant. It helps the paraffin wet the pigment better.

- Gloss enhancers, anti-break agents: resin such EVA, polyethylene wax, alkyd resin, ester gum or colophony (rosin derivatives), etc are added with a small amount to improve toughness and colour stick.

- Filler (Talc, clay, CaCO3): reduce price of product, simultaneously enhance hardness

2 – Production process:

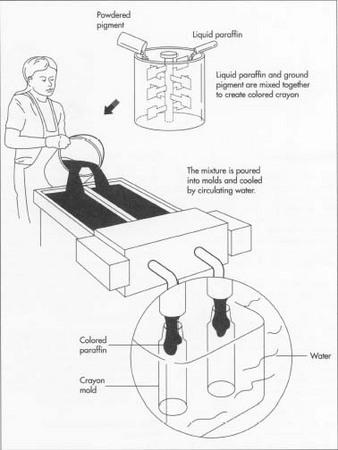

This figure simply illustrates the process of making crayon, in reality the process operates in large equipment automatically.

- Wax preparation

- Paraffin wax is melted at 60–80°C.

- Additives are blended in to adjust hardness and gloss.

- Critical parameters (CPs): temperature, consistent in liquid phase, no insoluble or foreign matter

- Color mixing

- Pigments are ground finely → mixed with molten wax in a heated mixer.

- Vigorous stirring ensures even dispersion, avoiding clumps.

- CPs: Good wetting, non-clumping

- Molding

- The hot mixture is poured into stick-shaped molds which make from steel or silicon/ or extruder.

- Cooling the crayons by cooling system with water or air solidifies.

- CPs: Non bubble, sticky in mould, craking due to rappid

- Finishing

- Crayons are removed from molds and contain in separated drawers for each colour

- The products are automatically wrapped with paper labels for handling and anti-sticking, then the crayons will be packed into boxes and cartons for shipping.

- CPs: non-cracked product after leaving mould, non missing label.

3 – Quality control:

Crayon before shipping must be meet these quality standard:

a. Chemical Safety for Raw Materials – International Standards: Depending on the target market, crayons must comply with the following regulations:

- Europe (EU):

- EN 71-1 / ISO 8124 – Mechanical & physical properties (durability, no detachable small parts that may pose a choking hazard).

- EN 71-2 – Flammability (must not be easily flammable).

- EN 71-3 – Migration of certain elements (limits on heavy metals such as Pb, Cd, Hg, Cr⁶⁺ in pigments and additives).

- United States (USA):

- ASTM D4236 – Toxicity assessment, requires labeling as “Non-toxic” if the standard is met.

- CPSIA (Consumer Product Safety Improvement Act) – Limits on lead and phthalates.

b. Attribute Testing:

- Hardness – measured using a compression machine (must not be too brittle).

- Fracture resistance – verified with repeated drop tests from 1 meter.

- Size & Weight – must be uniform and within product specifications.

c. Performance & Appearance Testing:

- Color consistency – must match the approved design and previous batch, uniform with no patchiness.

- Gloss (if glossy crayon) – checked under standard lighting conditions.

- Paper adhesion – colors must be vivid, provide good coverage, and spread smoothly without roughness or clumping.

- Surface quality – no cracks, chips, or critical damage; crayons must not be excessively sticky.

- Functionality – crayons must effectively coat the substrate (e.g., paper) with smooth application.

d. Sampling & Certification:

- Sampling inspection – performed according to AQL (Acceptable Quality Limit) standards.

- Test reports – certified by accredited laboratories (e.g., SGS, Intertek, TUV).

Leave a comment